An Introduction to E-CAP™ Silicon Capacitors

What is E-CAP?

Integrating multiple discrete capacitances into a single, integrated, solid-state device, E-CAP is the world’s thinnest, most compact and most flexible capacitor solution.

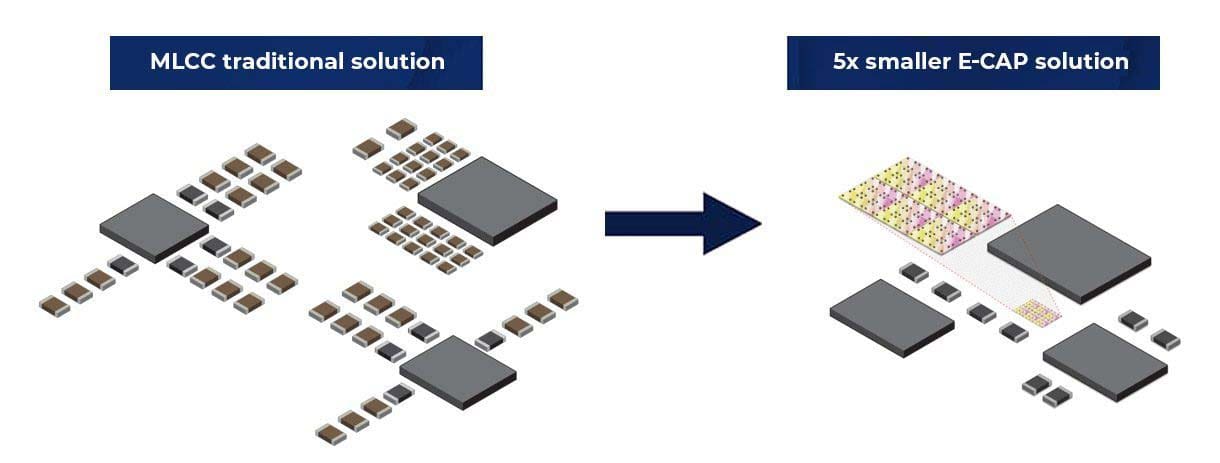

The technology brings together a capacitance solution density that is over five times that of leading multilayer ceramic capacitors (MLCCs) with improved equivalent series inductance (ESL) and equivalent series resistance (ESR) characteristics that dramatically reduce parasitics.

In addition, E-CAP can achieve thickness levels below 50µm, making it the thinnest capacitor technology available today. This makes the technology ideal for supporting next-generation, data-intensive systems that demand high-frequency operation and maximum efficiency from the smallest possible form factors.

E-CAP-based solution provides >5x density compared to standard MLCC

The primary benefit of E-CAP in a system is to provide a superior high-frequency de-coupling solution with a much smaller footprint and component count than traditional MLCC-based solutions. E-CAP also provides the added benefit of simplified design thanks to customizable form factors, flexible packaging options and negligible de-rating requirements.

Why do we Need E-CAP?

Used for energy storage, filtering, smoothing and tuning, the capacitor is one of the most basic and fundamental electronic components. However, capacitor development has not kept pace with the dramatic rate of change seen in the world of semiconductors and even leading technologies such as MLCCs are beginning to reach limitations. This is particularly true in next-generation, data-intensive, power-hungry applications when it comes to criteria such as size, performance, efficiency, stability, flexibility and reliability.

Empower identified the limitations of conventional capacitors while developing its family of integrated voltage regulators (IVRs). Determining that ‘off-the-shelf’ devices were not good enough for the demanding applications that IVRs address, the company developed its own capacitor technology to complement its IVR offering. The performance benefits of E-CAP have allowed the company to capitalize on the improvements that IVRs deliver over conventional power management solutions by providing, among other things, more flexible and superior voltage filtering that ensures very high accuracy during load transients.

Having proven the potential of E-CAP with its IVRs, the company is now offering E-CAP silicon capacitor solutions that allow engineers across a variety of demanding application areas to benefit from their superior performance, size and configurability and lifetime stability.

Simple and Flexible System Design

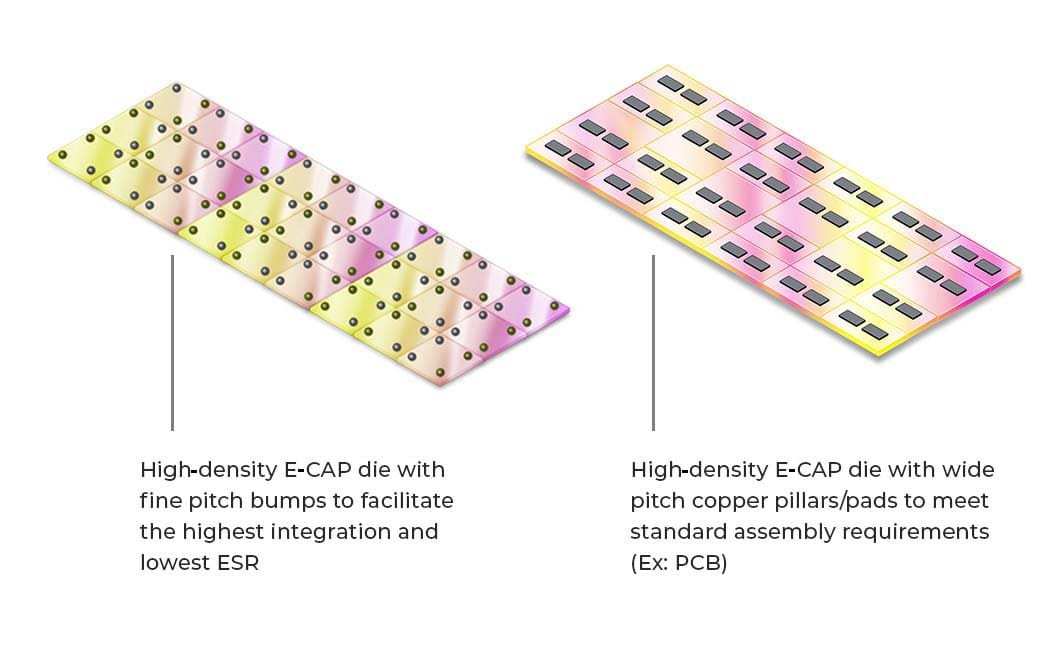

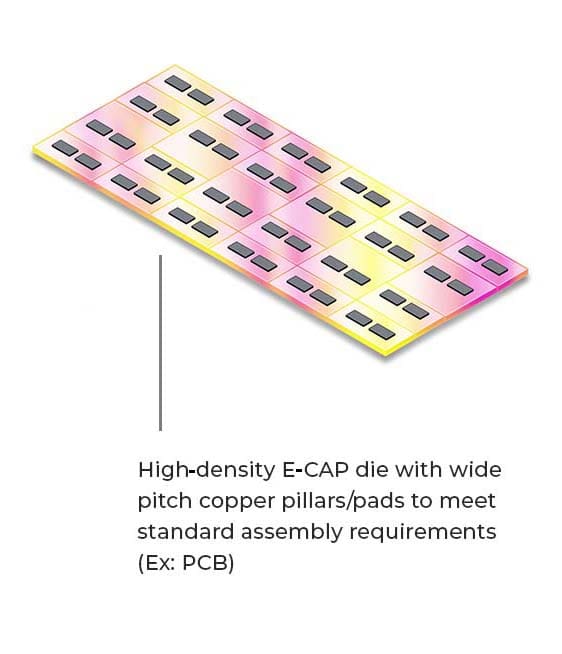

E-CAP offers unprecedented levels of flexibility for system designers. Multiple, matched capacitance values from 75pF to 5µF (@2V) can be integrated into a single die to create custom integrated capacitor arrays, while form factors can be customized for the space and height limitations of a particular application. Packaging options based on bumps, pads and pillars allow designers to choose the best solution based on specific system constraints.

And unlike MLCCs where multiple devices are needed to account for de-rating from voltage, temperature and age, E-CAP requires no AC or DC bias de-rating while all other de-rating requirements are negligible. This eliminates the need to ‘over spec’ capacitance requirements to account for de-rating.

| Parameter | Standard MLCC | E-CAP |

|---|---|---|

| Temperature de-rating | -11% up to 85°C | Negligible - ~0.3% (measured in ppm/K) - equivalent to COG |

| DC bias de-rating | 44% @ 3V | None |

| Aging | ~5-10%/10k hrs | <0.001%/10k hrs |

| ESL | >100pH (100nF) | <10pH (100nF) |

Simple and Flexible System Design

E-CAP offers unprecedented levels of flexibility for system designers. Multiple, matched capacitance values from 75pF to 5µF (@2V) can be integrated into a single die to create custom integrated capacitor arrays, while form factors can be customized for the space and height limitations of a particular application. Packaging options based on bumps, pads and pillars allow designers to choose the best solution based on specific system constraints.

And unlike MLCCs where multiple devices are needed to account for de-rating from voltage, temperature and age, E-CAP requires no AC or DC bias de-rating while all other de-rating requirements are negligible. This eliminates the need to ‘over spec’ capacitance requirements to account for de-rating.

| Parameter | Standard MLCC | E-CAP |

|---|---|---|

| Temperature de-rating | -11% up to 85°C | Negligible - ~0.3% (measured in ppm/K) - equivalent to COG |

| DC bias de-rating | 44% @ 3V | None |

| Aging | ~5-10%/10k hrs | <0.001%/10k hrs |

| ESL | >100pH (100nF) | <10pH (100nF) |

E-CAP Solutions

From mobile and wearables to data center servers and IoT devices, E-CAP opens up the possibility of deploying flexible, compact and high-performance capacitors with the proven reliability of silicon in a variety of demanding applications.

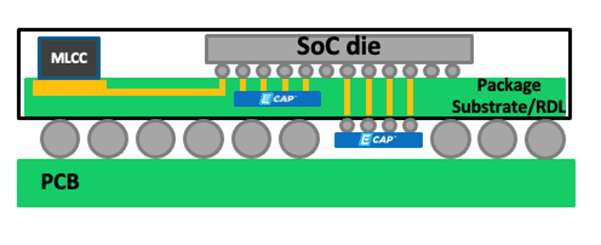

Ultra-low ESL – as low as 15pH compared to the 200pH of MLCCs – and package heights down to just 50µm make E-CAP ideal for in-package and under-package SoC and PCB filtering and bypass applications where it offers twice the capacitance density of the closest competitor and requires just one third the capacitance of MLCCs.

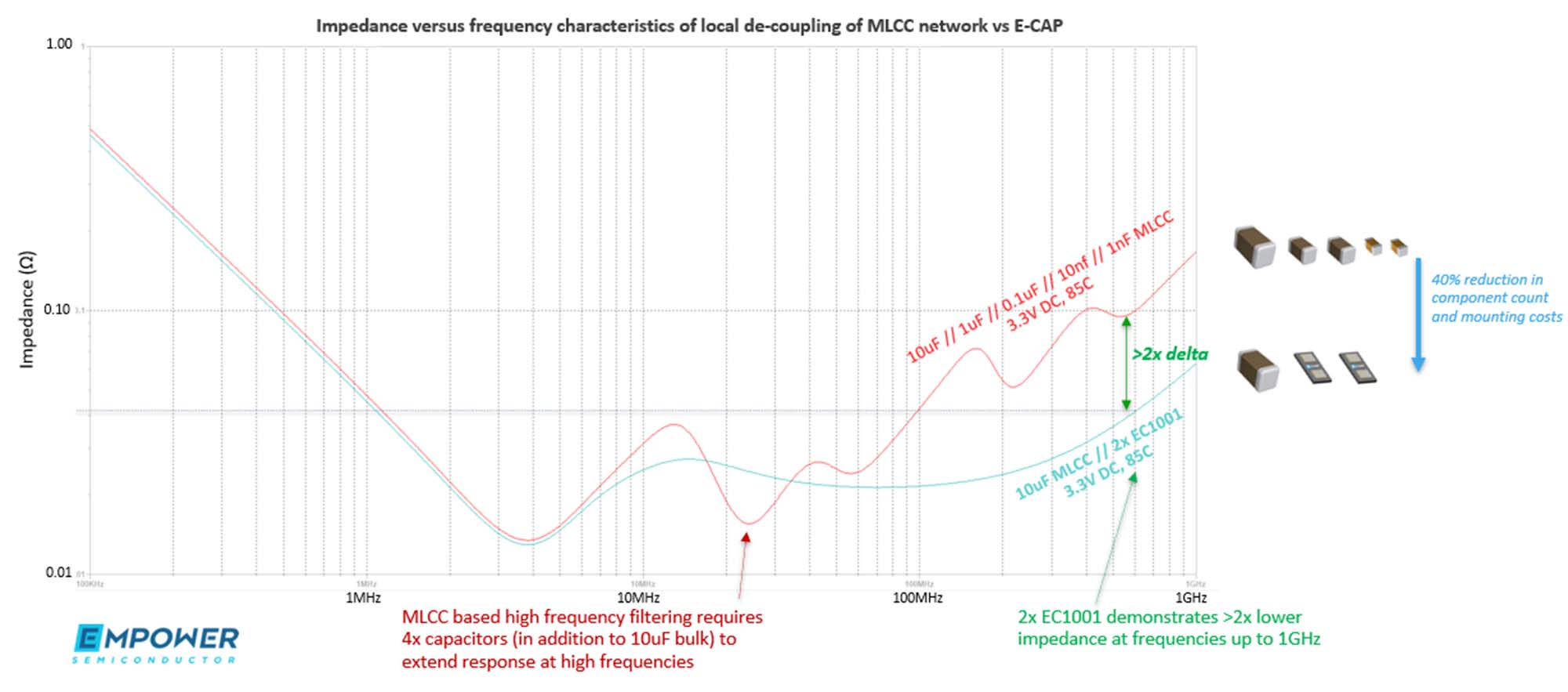

Using E-CAP, designers can combine all non-bulk, high-frequency decoupling capacitors into a single die to dramatically reduce component count, BoM cost and potential points of failure. Although the E-CAPs have lower nominal capacitance, their superior frequency response and ESL over MLCCs results in lower impedance at high frequencies.

As an example, the impedance versus frequency chart below compares a traditional implementation using multiple MLCC capacitors to extend the frequency response of a de-coupling solution, to that using E-CAPs instead of the high-frequency capacitors. The exercise demonstrates that the component count can be reduced by 40% through usage of E-CAPs while simultaneously lowering the impedance at high frequencies to half that achieved by the traditional MLCC based solution.