有源电缆

随着每一代数据中心连接的带宽翻倍,有源电缆即使不是短距离连接的主导,也将变得更加普遍。有源电缆有两种类型:有源电缆 (AEC),有时称为有源铜缆 (ACC),以及有源光缆 (AOC)。两种类型的可插拔收发器都与多股铜缆或光纤电缆永久连接在一起。所有可插拔收发器,无论是铜线还是光纤,都使用行业标准的 3.3V 电源运行,它们必须从中获得内部所需的电源轨。根据所部署的半导体技术,这可能只是几条轨道或多达八到十条。

一般来说,实现AEC所需的电源轨比AOC少,目前至少一家AEC商业硅供应商提供单一个电压轨–3.3V的方案。由于这种简单性,我们将集中讨论AOC,其电源需求更为复杂。

AOC的结构通常与普通的光收发器一样,需要激光器、激光器驱动器、TIA(跨阻抗放大器)和CDR(时钟和数据恢复)等硅结构块。由于AOC的定义是短距离,VCSEL激光器是首选的激光器。高性能的400G收发器可能还需要额外的组件,如DSP。

AOC 通常由与常规光收发器相同的硅构建块构成,因为它们需要激光器、激光驱动器、TIA(跨阻抗放大器)和 CDR(时钟和数据恢复)。由于 AOC 根据定义是短距离的,因此 VCSEL 激光器是首选激光器。高性能 400G 收发器可能还需要额外的组件,例如 DSP。

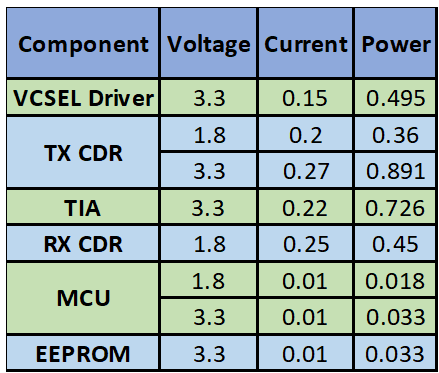

在构建 400G AOC 时,可以选择 4 个 100G 通道或 8 个 50G 通道。由于 50G 通道是较老、更成熟的技术,50G 通道的成本将低于 100G 通道,因此大多数 400G 电缆最初将使用 8x50G 配置。 IEEE对50G的8个lane进行了标准化,命名为400GBASE-SR,简称400G-SR8。虽然该标准不适用于 AOC,但相同的芯片主要用于设计收发器和 AOC。而且至少有一个芯片组不使用 DSP。这样的实现可能会使用以下电源轨。

Table 1: non-DSP AOC Power Rails

在本例中,我们只处理两个电压:1.8V 或输入源 3.3V。可以使用单个 1.8V 1A 降压转换器为该架构提供电源,我们可以使用 3.3V 输入 Empower IVR 来生成此电源轨。

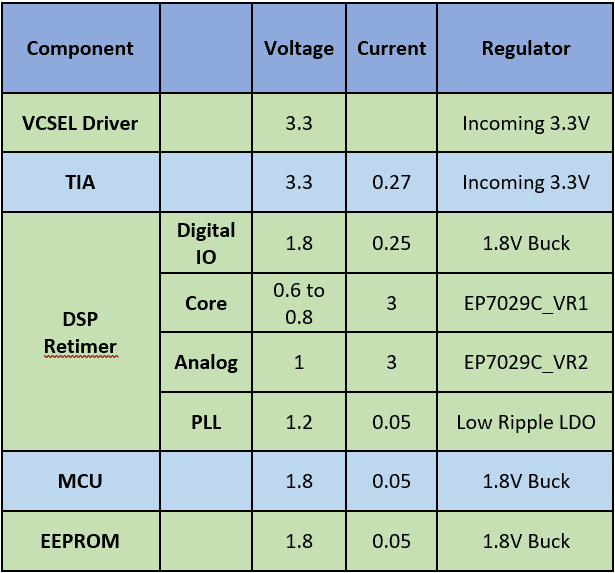

DSP 实现将具有更复杂的电源树。 CMOS DSP 通常需要几个电源:核心数字、数字 I/O 和一个或两个模拟电源轨,如表 2 所示。

Table 2: DSP-Based Power Rails

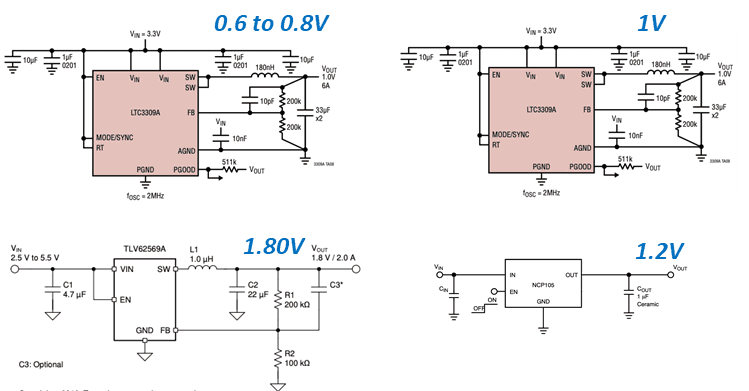

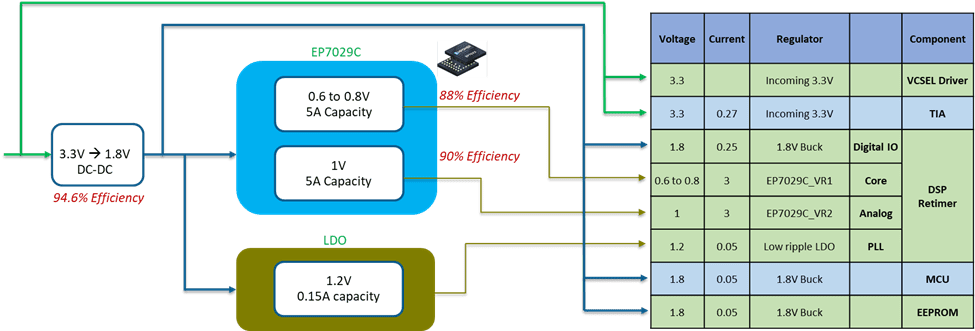

创建表 2 中电源轨的传统方法是使用分立降压转换器。图 1 中提出了基于该方法的解决方案。

Figure 1: Discrete Converters to Address Power Rails in Table 2

这种方法很实用——它可以完成工作,但需要 45 个组件和大约 360 平方毫米的 PCB 空间,系统效率为 88%。图 2 显示了使用 Empower IVR 的替代实施

Figure 2: Empower IVR to Address Table 2 Power Rails

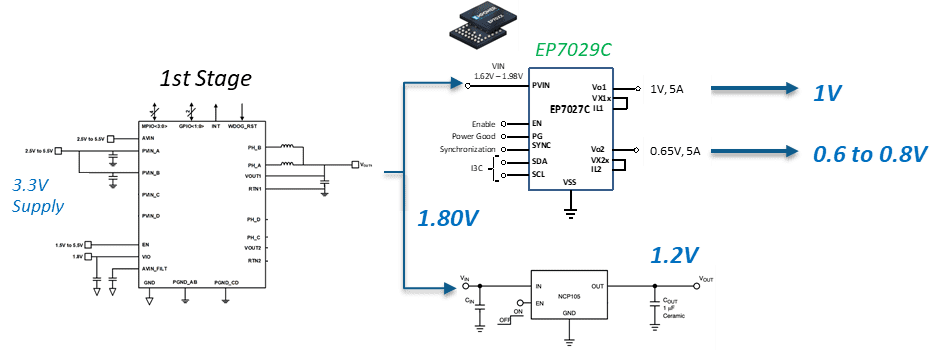

使用 Empower 方法的目标是减少组件数量和电路板占用空间。所示的 EP7029C 处理 DSP 的内核和模拟轨。为了给 EP7029C 供电,使用大尺寸1.8V 电源轨,以便它可以偏置 IC 并仍然为其他负载供电。 Empower 方法实现了占位面积和 BOM 减少的目标,因为组件的总数减少到只有 15 个,PCB 面积缩小到 155mm2。系统效率仍然是可观的 85%,考虑到组件减少 3 倍和面积减少 2 倍,这是可以实现的最佳结果。图 3 显示了该电路的实现。

图3:Empower IVR电路实现表2电源导轨

随着设计人员不断被要求将更多功能集成到更小的空间中,电源设计正受到前所未有的挤压。虽然传统的降压稳压器技术以尺寸换取效率,但 Empower IVR 可以通过提供两全其美的方式来避免这种妥协。