SmartNICs

随着世界对带宽需求的飙升,现代数据中心的规模和复杂性必须增长以满足需求。数据中心网络正在多个领域发展以满足处理负担。很多注意力都集中在将处理分布在整个网络结构上。架构中添加了可编程和智能处理的一个位置是网络接口卡 (NIC)。包含这种附加处理能力的 NIC 称为 SmartNIC。

SmartNIC 可以按实现分为 3 类:用 ASIC 实现的、用 FPGA 实现的和用 SOC 实现的。这些实现中的每一个都将具有不同的电源需求,具体取决于它们使用的硅器件,但它们都将共享一个公共输入电压 – +12V。让我们看一个实际设计中的 ASIC 示例。

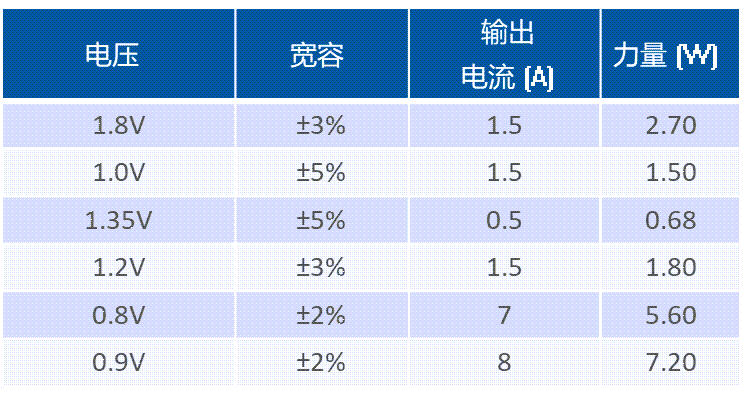

此处使用的示例有 6 个电压轨 @1.8V 及以下。如前所述,输入源为 12V。从 12V 降压至其他电源轨的一种简单方法是使用单级降压稳压器直接从 12V 降压至所需的输出电压。我想到了两种方法。第一种方法是使用所有带有分立电感器和电容器的分立转换器。这种方法可以以牺牲所有其他设计因素(包括电路板空间和组件数量)为代价来优化效率。在 650-700 mm2 的电路板空间中,对于这 6 个导轨,这种方法的高质量实施将产生大约 90% 的效率,大约有 90 个组件。

第二种方法可能是对问题进行一些集成,并使用集成了电感器的电源模块。这种方法简化了设计,因为设计工程师不再需要参与工程或采购工作来选择和布局电感器等组件。同时,它减少了组件数量并缩小了设计,但往往以牺牲效率为代价。一个知名的实施方案会将电路板空间减少到 500-550 mm2,组件数量减少到大约 40 个。不幸的是,效率也呈下降趋势。在这种情况下,效率计算为 81%。

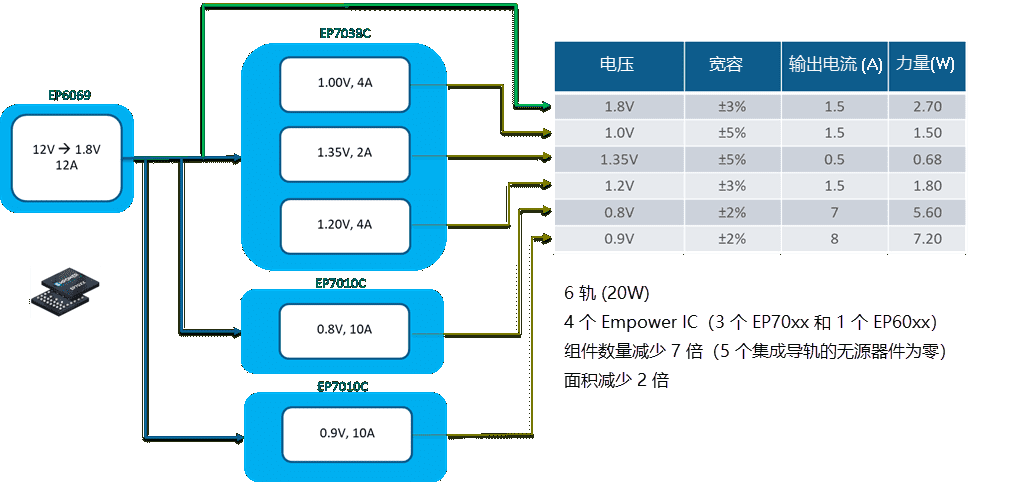

总而言之,第一种方法以牺牲电路板空间和组件数量为代价来优化效率,而第二种方法以牺牲效率为代价来优化简单性和组件数量。相比之下,Empower Semiconductor 使用集成稳压器 (IVR) 提供了独特的第三种方法。通过 Empower 方法,我们创建了一个高效的 1.8V 第一级,它提供 1.8V 负载,并为 IVR 设备提供输入,从而创建所有低于 1.8V 的电源轨。

这种方法比之前介绍的模块方法更好,因为它只需要大约 320 mm2 的电路板空间和 12 个组件即可实现。整体效率达到了可观的 86%。

随着设计人员不断被要求在更小的空间中集成更多功能,电源设计正受到前所未有的挤压。传统的降压稳压器技术以尺寸换取效率。 Empower IVR 可以避免这种妥协,并提供两全其美的优势。